|

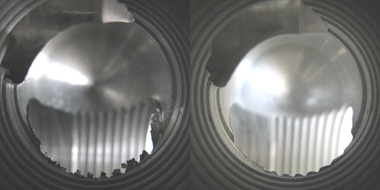

Inside an aluminium hydraulic block where crossholes open out into threaded holes.

Non selective deburring of complex features but leaving M3 threads intact.

2 intersecting angled cross holes into a main bore.

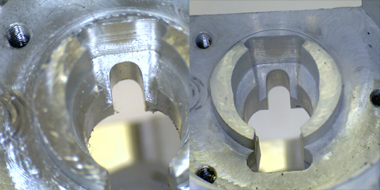

3 & 5 mm diameter holes in a steel component.

1.5 mm slot at the bottom of a 4mm diameter hole.

.

.

5mm threaded jets

Stainless

80% of these jets produced an erratic spray pattern before thermal deburring. After thermal deburring only 10% did.

.

.

.

.

.

.

.

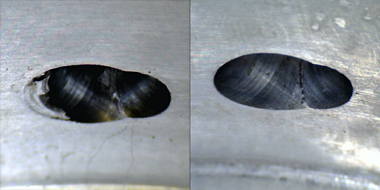

Before and after 1 - 10x magnification

Stainless steel

Whisker burrs on milled edge inside component. Guaranteed removal of ALL burrs and whiskers. .

.

.

.

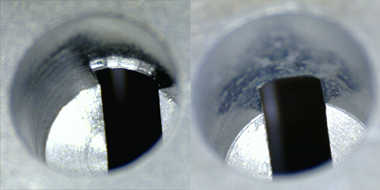

Before and after thermal deburring 2

50 diam x 20mm

Steel

Parts took 15 mins each to deburr by hand - 20 milliseconds by TEM

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Mechanism housing

25 x 50 x 70mm

Zinc die cast part

Excessive flashing removal

.

.

.

.

.

.

.

.

Hydraulic control sleeve

15 diam x 50mm

Turned steel

Intersecting cross holes deburred

No damage to seating edges

.

.

.

.

.

.

.

. .

.

Pinion

50 diam x 175mm

Steel

Removal of burrs from milling on all teeth edges in one go, saving costs and time.

....

..

.

..

..

Electronic component

20 diam x 5mm

Stainless steel

Their client rejected entire batches of 5,000 if one burr was found. TEM is the only process that could guaranteed no burrs

..

..

..

..

..

..

..

..

..

..

Carburettor body

150 x 150mm

Zinc die cast

Flash and machining burrs removed in one pass

Inaccessible intersecting holes, successfully deburred

All debris and particles removed

..

..

..

Blanking plates

20 diam x 10mm

No other method of deburring could provide the consistent high quality needed

Run 20,000 components every week

.

.

.

.

..

..

Tank probe

20 mm high

Stainless steel

Very fine burrs at cross holes needed to be removed without damage to internal bore

..

..

..

..

..

Control Sleeve

20 diam x 200

Steel

Multiple load means components deburred concurrently

Saving time and costs

..

..

Sleeves

22 diam x 45mm

Steel

Cross holes needed to be guaranteed burr free.

..

..

..

..

..

Fitting

75 x 75mm

Brass

Milling and drilling burrs removed

Awkward burrs at hole intersections

..

..

Pressure manifold

38 x 38 x 43mm

Stainless steel

Awkward to reach internal burrs - easily missed. Process stipulates TEM to guarantee certificate of conformity.

..

..

..

..

..

..

..

..

Gear wheel

100 diam x 60

Steel

Burrs from milling and broaching removed

Critical tooth dimensions not affected

..

..

..

..

Pump housing

90 x 95 x 50mm

Cast iron

TEM used to avoid time consuming hand deburring and human error, and the need to remove all contamination

..

..

..

..

..

..

..

..

..

..

Bearing cage

70 diam x 30mm

Steel

Broaching burrs removed

Potential loose particles eradicated

Surface of component left untouched

..

..

..

Medical air compressor end unit

70 x 50 x 40mm

Aluminium

All contaminants and potential loose pieces needed to be guaranteed to be removed

Human variables and errors unacceptable

..

..

..

..

.

..

..

Cage

240 diam x 280mm

Aluminium die cast

All burrs from casting and drilling removed

Avoiding human error

Time savings

..

.

..

Hydraulic manifold block

150x 140x 170mm

Steel

TEM saved 80% of hand deburring costs and avoided human error.

..

..

..

..

..

..

..

..

..

..

Hydraulic manifold block

150x 120x 290mm

Aluminium

TEM guaranteed consistent high quality across EVERY hole, component, batch and run

. .

..

.

.

..

.

.

.

.

. |